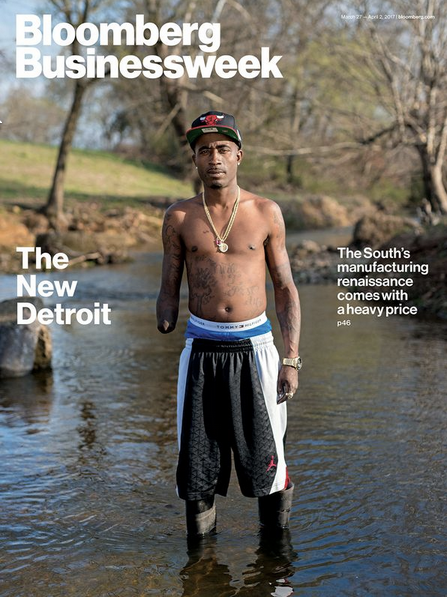

The South’s manufacturing renaissance comes with a heavy price.

Alabama has been trying on the nickname “New Detroit.” Its burgeoning auto parts industry employs 26,000 workers, who last year earned $1.3 billion in wages. Georgia and Mississippi have similar, though smaller, auto parts sectors. This factory growth, after the long, painful demise of the region’s textile industry, would seem to be just the kind of manufacturing renaissance President Donald Trump and his supporters are looking for.

Except that it also epitomizes the global economy’s race to the bottom. Parts suppliers in the American South compete for low-margin orders against suppliers in Mexico and Asia. They promise delivery schedules they can’t possibly meet and face ruinous penalties if they fall short. Employees work ungodly hours, six or seven days a week, for months on end. Pay is low, turnover is high, training is scant, and safety is an afterthought, usually after someone is badly hurt. Many of the same woes that typify work conditions at contract manufacturers across Asia now bedevil parts plants in the South.

“The supply chain isn’t going just to Bangladesh. It’s going to Alabama and Georgia,”